How to Calibrate and Maintain Acceleration Sensors for Long-Term Performance?

A Practical Guide for Russian Companies to Extend Sensor Lifespan If your company operates in Russia’s industrial, aerospace, or energy sectors, you’ve likely encountered a common challenge: accelerometer sensors in extreme climates or high-vibration environments often suffer from data drift or performance degradation. This not only compromises measurement accuracy but can also lead to costly downtime.Don’t worry—this guide, written by engineers for engineers, shares actionable calibration and maintenance strategies tailored to Russia’s unique conditions. Learn how to maximize sensor lifespan and minimize operational risks. Why Calibration and Maintenance Matter for Russian Businesses Russia’s vast geography exposes sensors to harsh conditions: Real-World Consequences of Neglect:✅ A Moscow-based automotive testing facility lost 2 million RUB due to uncalibrated sensors causing 15% data deviation in vehicle vibration tests.✅ Sensors at an Arctic research station failed due to condensat

How to Choose High-Precision Accelerometers for Industrial Automation?

Industrial automation in Russia is rapidly evolving, driven by sectors like manufacturing, energy, and transportation. High-precision accelerometers are critical for tasks such as vibration monitoring, predictive maintenance, and machinery diagnostics. However, selecting the right sensor requires balancing technical specifications, environmental demands, and cost efficiency. Here’s a practical guide to making informed decisions, backed by real-world data and industry insights 1. Define Your Application Requirements Start by understanding your specific use case. For example: Key Metrics to Prioritize: 2. Evaluate Technical Specifications a) Sensitivity and Dynamic Range High-precision accelerometers must detect subtle vibrations without saturating at high amplitudes. For example: b) Power Consumption and Connectivity Wireless and IoT-ready sensors are gaining traction in Russian factories. The FXLS8971CF (NXP Semiconductors) consumes minimal power (≤20 µA) and supports indust

How Harsh Environments Can Sabotage Your Accelerometer Sensor?

In the rugged landscapes of Russia, where extreme temperatures, high humidity, and corrosive environments are the norm, the performance of acceleration sensors can be severely compromised. Imagine a scenario where your industrial machinery relies on precise vibration monitoring, but the sensors fail due to harsh conditions. This isn’t just a hypothetical situation; it’s a common challenge faced by industries across the board. The Real Impact of Harsh Environments When it comes to acceleration sensors, environmental conditions can make all the difference. High temperatures can cause silicon-based sensors to degrade, as silicon experiences plastic deformation at around 500°C. Extreme cold can affect the sensitivity and accuracy of sensors, while high humidity and corrosive substances can lead to material degradation and signal interference. But what does this mean in practical terms? Let’s dive into some real-world data. Real-World Data and Insights Recent studies have

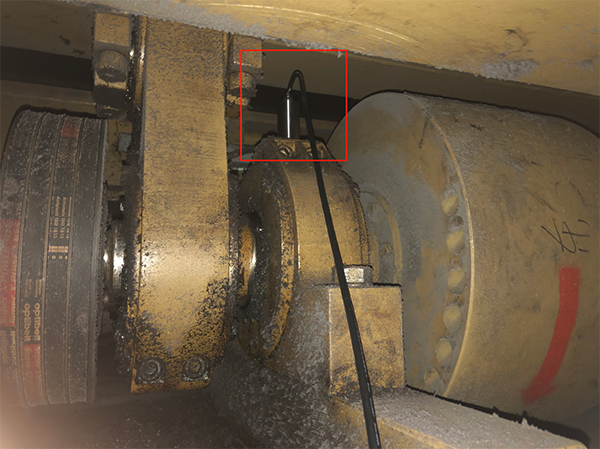

How to Optimize Mechanical Vibration Monitoring with Acceleration Sensors ?

Mechanical vibrations are a common phenomenon in industrial environments, and their effective monitoring is crucial for maintaining the health and efficiency of machinery. Acceleration sensors play a vital role in this process by providing precise data on vibration patterns, which can help identify potential issues before they escalate into costly failures Real-World Applications of Acceleration Sensors in Vibration Monitoring Let’s dive into some practical examples to illustrate how acceleration sensors can be used to optimize vibration monitoring: Tips for Optimizing Vibration Monitoring Conclusion Acceleration sensors are indispensable tools for optimizing mechanical vibration monitoring. By leveraging these sensors, industries can enhance equipment reliability, reduce maintenance costs, and improve overall operational efficiency. Whether it’s a rotating motor in a factory or an aircraft engine, the right sensors and monitoring strategies can make a significant differen

How to Choose the Best Acceleration Sensor for Your Industrial Application

Acceleration sensors are essential tools in various industrial applications, from monitoring machinery vibrations to ensuring the stability of structures. Selecting the right acceleration sensor for your specific needs can significantly impact the efficiency and reliability of your operations. This guide will help you understand the key factors to consider when choosing an acceleration sensor for your industrial application. Understanding the Basics of Acceleration Sensors Acceleration sensors, also known as accelerometers, measure acceleration forces. These forces can be static, like gravity, or dynamic, such as those caused by vibration or motion. The working principle of most accelerometers is based on Newton’s second law, where the inertial force applied to a mass block is measured to obtain the acceleration value. Types of Acceleration Sensors Key Parameters to Consider Application-Specific Considerations Installation and Calibration Proper installation and calibration are

What Are the Key Applications of Accelerometer Sensors in Aerospace?

In the aerospace industry, precision and reliability are non-negotiable. Whether it’s an aircraft, satellite, or spacecraft, every component must perform to the highest standards. Accelerometer sensors, as a critical component, play an indispensable role in these high-end applications. This article explores the advanced applications of accelerometer sensors in the aerospace field and explains why they are essential for your projects. What is an Accelerometer Sensor? An accelerometer sensor is a device used to measure acceleration—the rate of change in velocity. It detects an object’s motion, including vibration, tilt, and shock. In aerospace, this data is crucial for ensuring flight safety and optimizing performance. Key Applications of Accelerometer Sensors in Aerospace Why Choose High-Quality Accelerometer Sensors? In aerospace, the accuracy and reliability of sensors directly impact mission success. High-quality accelerometer sensors offer the following advantages: How to Choose th

High-Temperature Accelerometer Sensors: Your Complete FAQ Guide

For engineers and maintenance professionals working in extreme heat environments, high-temperature accelerometer sensors are mission-critical tools. Yet, misconceptions and technical queries about their capabilities persist. This FAQ guide combines 20+ years of industry expertise and 2024 market data to address your most pressing questions. 1. What Is a High-Temperature Accelerometer Sensor? High-temperature accelerometers measure vibration and shock in environments exceeding 150°C (302°F), with advanced models operating up to 550°C (1022°F). Unlike standard sensors, they feature: Key Fact: According to a 2023 Grand View Research report, the high-temperature sensor market will grow at 7.2% CAGR through 2030, driven by energy and aerospace demands. 2. How Do I Choose the Right Sensor for My Application? Parameter Gas Turbines Steel Mills Geothermal Plants Temp Range 200-450°C 150-350°C 250-500°C Frequency Response 2-10,000 Hz 5-5,000 Hz 1-8,000 Hz Shock Resistance 5

How 300°C-Rated Accelerometers Prevent Turbine Blade Failures in Aerospace: A Data-Backed Case Study

Introduction In the high-stakes world of aerospace, turbine blade failures cost an estimated $2.4 million per engine shutdown (2023 NTSB Report). Traditional vibration sensors often fail under extreme operating temperatures, leaving engineers blind to critical blade health data. This case study reveals how 300°C-rated IEPE accelerometers enabled real-time monitoring of CFM56 jet engine blades, reducing unplanned maintenance by 72% at a major European airline. The Challenge: When Standard Sensors Melt The Solution: Engineering a High-Temperature Trio Three breakthrough technologies converged: Implementation: From Bench Test to Flight Certification Phase 1: Ground Testing Phase 2: In-Flight Monitoring Results: Lessons Learned: 3 Rules for High-Temp Aerospace Sensing Conclusion The era of “flying blind” in jet engine monitoring is over. Next-gen 300°C accelerometers now provide: ✈️ Go to Download Our Ultra-high temperature acceleration sensors manual.

5 Critical Specifications That Determine the Success or Failure of Industrial Accelerometer Selection (With Comparison Table)

Introduction Industrial accelerometers are vital for monitoring vibration, shock, and motion in harsh environments—from heavy machinery to aerospace systems. However, selecting the wrong sensor can lead to inaccurate data, equipment failure, or costly downtime. This blog breaks down the 5 key specifications that define accelerometer performance and provides actionable insights to guide your selection process. 1. Measurement Range (±g) Why It Matters: The measurement range defines the maximum acceleration force (in g-force) the sensor can accurately detect. Exceeding this limit causes signal clipping or sensor damage. Key Considerations: 2. Sensitivity (mV/g or pC/g) Why It Matters: Sensitivity determines how effectively the sensor converts mechanical motion into an electrical signal. Higher sensitivity suits low-frequency vibrations; lower sensitivity avoids saturation in high-g environments. Trade-offs: 3. Frequency Response Why It Matters: The frequency range (Hz) a sensor can a